Hot-dip galvanizing is the process of immersing your steel platform in a bath of molten zinc. Why choose a galvanized deck? For its high corrosion resistance, durability and versatility.

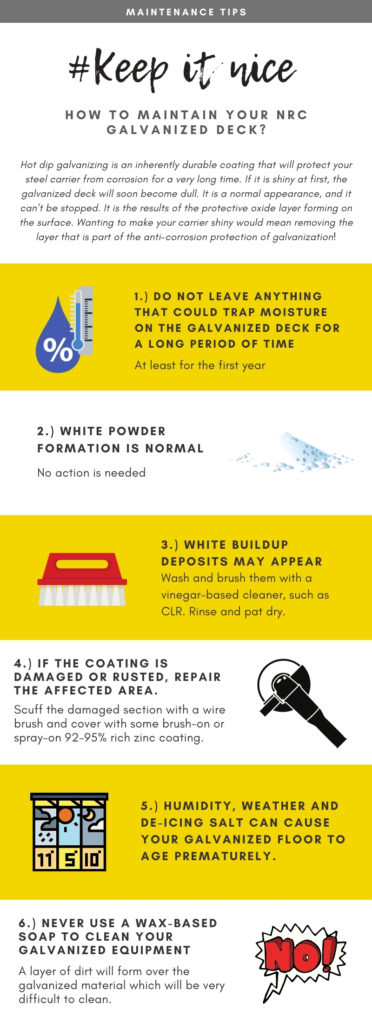

Hot dip galvanizing is an inherently durable coating that will protect your steel carrier from corrosion for a very long time. If it is shiny at first, the galvanized deck will soon become dull. It is a normal appearance, and it can’t be stopped. It is the result of the protective oxide layer forming on the surface. Wanting to make your carrier shiny would mean removing the layer that is part of the anti-corrosion protection of galvanization!

> My galvanized deck is looking dull

No stress here. This is completely normal, and even desirable! After a few days of exposure to the atmosphere, the zinc reacts with the ambient elements and a gray or whitish patina forms on the surface of the deck. The insoluble layer thus formed offers additional protection to your galvanized carrier against corrosion. More protection, less shine. We personally think it’s a good deal.

> There are white deposits on the deck of my carrier

These whitish spots, commonly known as “white rust”, appear when water or condensation has formed from certain items transported or stored on the carrier. For example, wooden pallets left on the deck for a long period of time.

The only drawback of this phenomenon is aesthetic. It doesn’t affect the quality of the galvanization in any way.

> Should I wax my galvanized deck?

No, please no! Applying wax to your galvanized carrier will add an extra coat which will collect dirt. It will then be very difficult to clean from the deck. You should never use wax or wax-based cleaner on your galvanized equipment.

Your galvanized carrier offers incomparable advantages in terms of durability. To keep it nice for a long time, follow these tips!

- Do not leave anything that could trap moisture on the galvanized deck for a long period of time, at least for the first year.

- If you see a white powder form in some places, it is normal. No action needed.

- White deposits may appear over time if exposed to moisture. Wash and brush them with a vinegar-based cleaner, such as CLR. Rinse and pat dry.

- If the coating is damaged or you see rust, you can repair the affected area. Scuff the damaged section with a wire brush and cover with some brush-on or spray-on 92-95% rich zinc coating.

- Note that humidity, weather and de-icing salt can cause your galvanized floor to age prematurely.

- Never use a wax-based soap to clean your galvanized equipment. A layer of dirt will form over the galvanized material which will be very difficult to clean.